Top Seven Must-to-do Things for Efficiency Improvement

Efficiency can be defined as amount output derived from inputs. it is directly linked to resource optimization. Today business environment is very competitive & cost of product plays vital role in driving sales. Let’s discuss top Seven Must-to-do Things for Efficiency Improvement. The cost of production is depended on raw material, labour, overheads etc. The way any company uses these resources derive the final cost of product. There are many tools available for using these resources more efficiently. Seven mostly used & simple tools are summarized as below:

- Visual Management: The items placed at workplace should talk to us. few examples are:

- The instruction board on machine should tell how to operate, what alarms to look for etc.

- The color coding should tell which cylinder has which gas.

- The production board should tell, target for the day, week or month & status and so on.

- Posters with information on risk, procedures etc.

- Labels like Hold, Out of Service

- 5S: This is the basic tool which is based on principal that, the work place should be clean, sorted, standardized, Systematic & sustainable. The terms are common to many industries viz. Sort, Set-in-order, Shine, Standardize & Sustain. Utlities like shadow boards, Peg boards are very helpful for organizing the work place. Red tag system is the starting of 5S in a company. Small 5S kit are available for start the 5S journey & feel the benefits of it’s fruits.

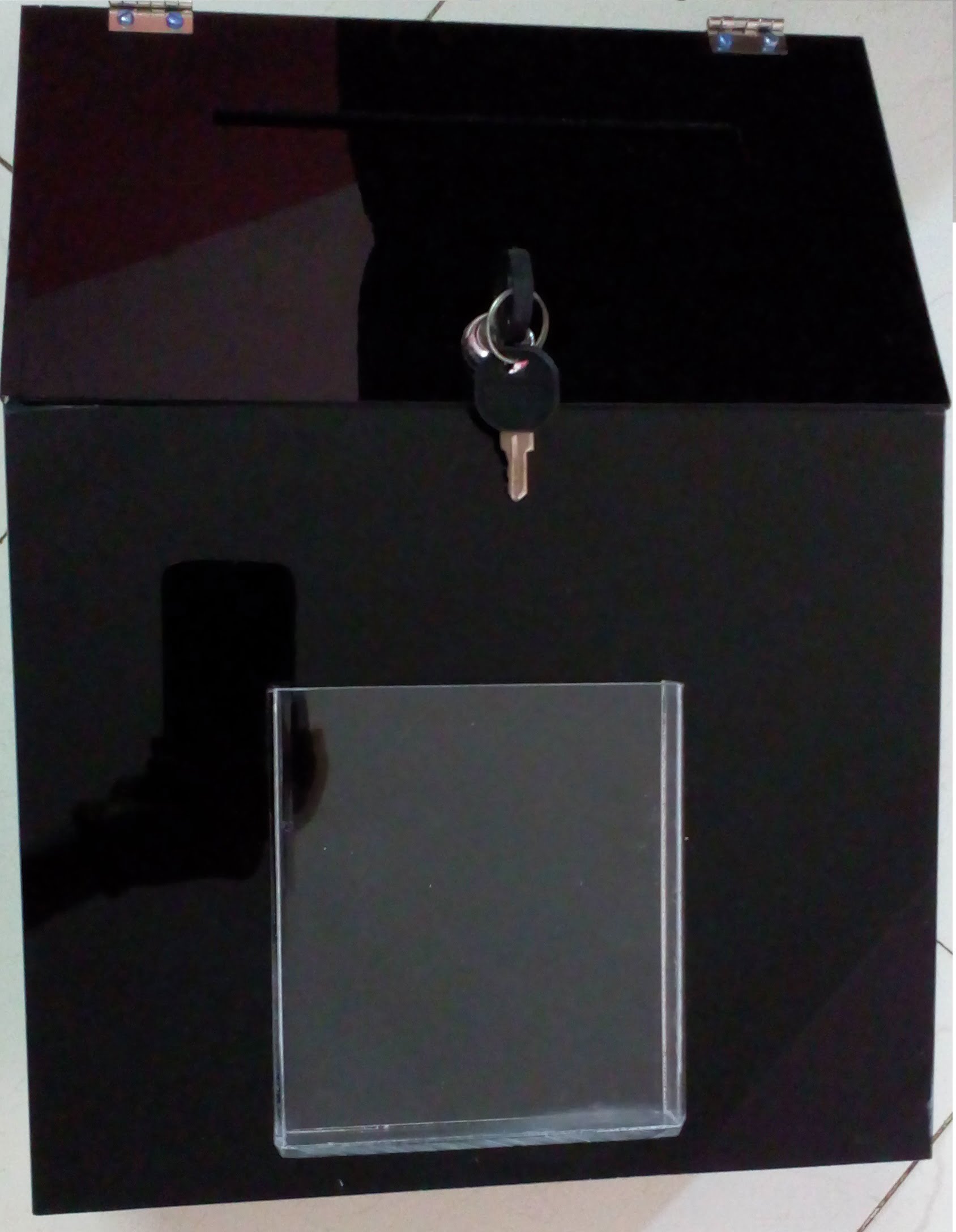

- Kaizen: Suggestion are nobody’s monopoly and can come from any level in organisation. Every Suggestion has to be treated with due respect. Culture shall be created to invite and motivate the whole team to contribute with ideas. These ideas shall be evaluated & awarded to get the system going. Small improvement in system result in continuous improvement. Simple Suggestion box & formats are only required to begin the kaizen system.

- Safety Culture: Safety is not directly linked with production but any unwanted accident can result in loss of asset, life & reputation & has potential of completely shutting down the business.

- Skill Development: Skill is a diminishing inventory if not used & upgrdaed with time. Thus, two things are very important. One is to use right skill at right place at right time, otherwise this will got wasted. Other is to continuously upgarde the skill level to be in pace with changing requirement. Inhouse training should also be given to team for refreshing the concepts.

- Integration of Information Technology: IT has got in to every sphere of life, be it industry or society. A company shall use IT to leverage its power to make the systems more efficient. Data capture & analytics has become a big thing in today’s scenario. If a company is not on internet, it is lacking share of market to it’s competitors.

- Seven Basic Quality Tools: These Seven quality tools include cause and effect, Check sheet, control chart, Histogram, Pareto chart, Scatter Diagram & Stratification. These are most basic tools which should be applied to work environment to identify the root cause & design solution.

These are only few of the tools which are very important to bring up the efficiency of any company’s work environment.

#Top Seven Must-to-do Things for Efficiency Improvement

For 5S utility product on amazon Click Here